High Quality Sheet Metal Press Brakes

Over 1,000 machines installed.

We are Novastilmec partners, to whom we build and service a wide range of sheet metal press brakes.

The reliability and precision developed over many years of experience in design and manufacturing are combined with the new opportunities offered by modern electronics and information technology to make solid, technologically advanced, reliable, precise and extremely flexible machines.

In addition to the wide range of offerings already available, customized and specific solutions can be studied according to the production needs of individual customers.

Our sheet metal press brake is a testament to technological evolution. Based on a solid foundation of technology derived from standard press brakes, it has been reworked to meet the specific needs of the sheet metal industry. With an exceptionally robust construction, it is designed to meet the challenges of sheet metal working flawlessly.

Our press brake represents the pinnacle of technology applied to the sheet metal industry. It is solid and reliable, built to last and meet tough challenges. Built-in technology ensures unparalleled precision, while advanced features such as the press brake and back registers make your work more efficient.

Modern tinsmithing requires machines that rise to the challenges. Our press brake is ready to take you to the next level of excellence. Contact us today and find out how this machine can improve your productivity and the quality of your sheet metal projects.

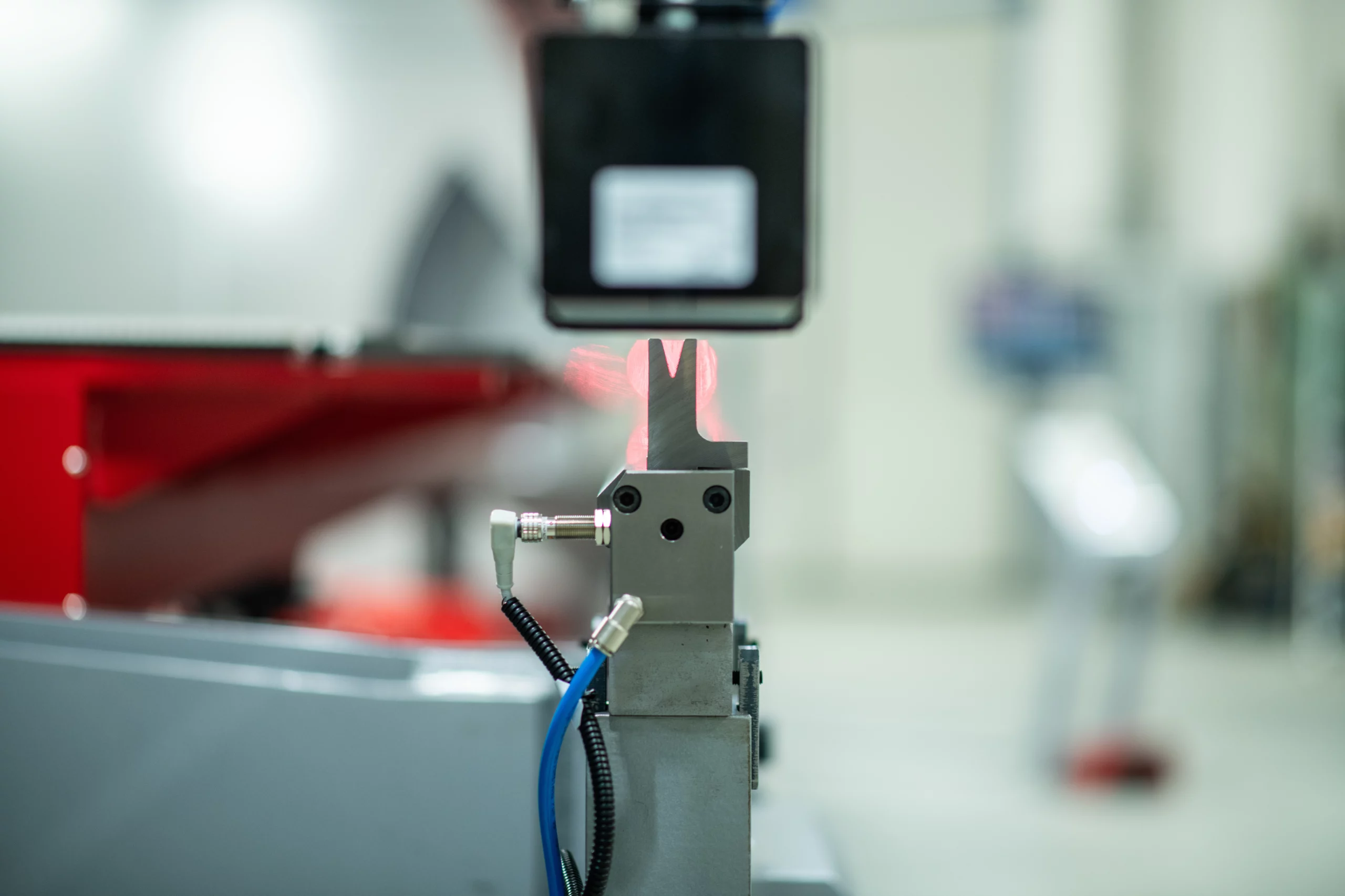

- Built-in folding: Our press brake is equipped with an integrated bottom-table bender fully controlled by CNC or with single bender with built-in die making the bending process much more efficient.

- 750, 850, or 1000 socket: We offer flexibility with 750, 850 or 1000 recess options, so you can choose the size that best suits your needs and the type of work you plan to do.

- Advanced Rear Registers: Our rear register system is state-of-the-art. Equipped with 2 axes (X and R), it offers a stroke of 1500 mm on X and 250 mm on R, along with a 600-mm-wide rear platform with the option of adding brushes to safeguard material integrity. This ensures accuracy and repeatability in bending, minimizing errors.

- Active shelling or wila table: Our sheet metal press brake offers superior flexibility and accuracy. We have the ability to mount both active crowning and wila table, being able to achieve perfect, linear bends on any type of material.

- Extreme Versatility: Our press brake is designed to handle a wide range of sheet metal projects. Whether you need to create gutters, roofing, skylights or other components, this machine is ready to meet your needs with versatility and precision.